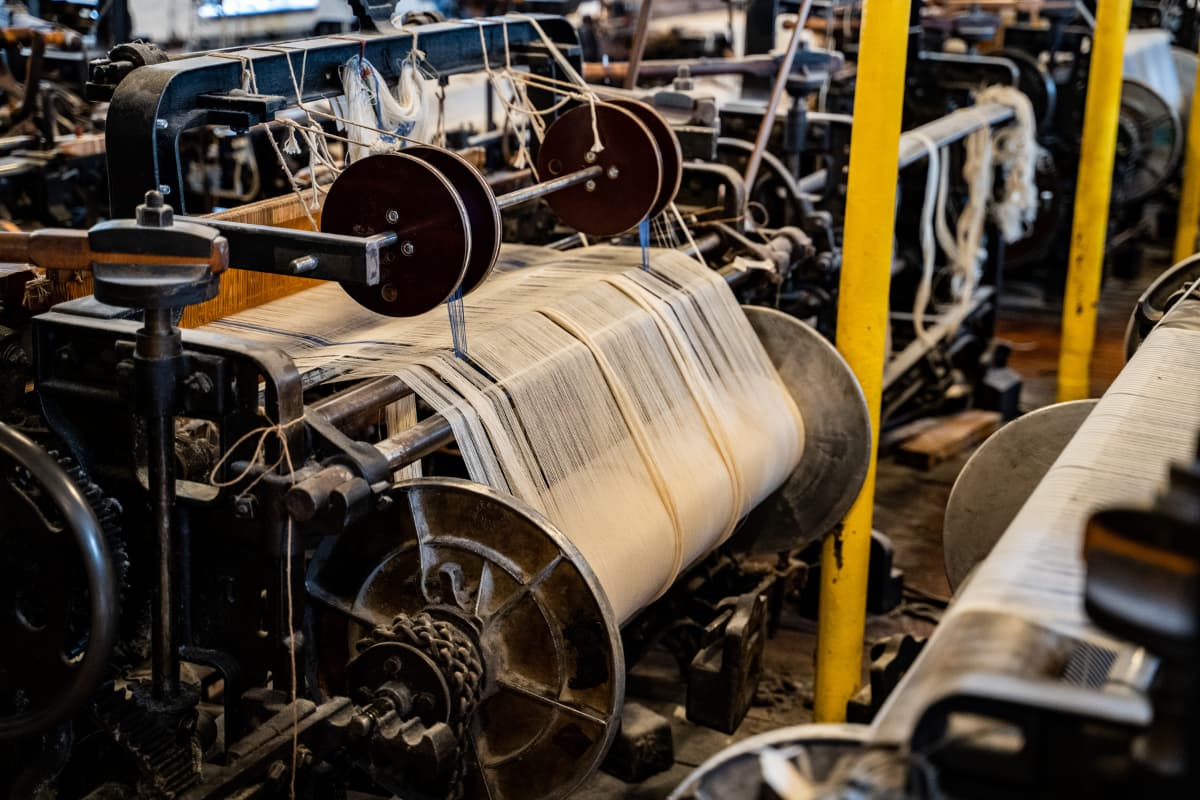

The factory floor of the past, with its noisy gears and human-centric processes, is rapidly being replaced by a new, smarter reality. In this new era, machines communicate with each other, data dictates decisions, and production is more efficient and sustainable than ever before. This is the fourth industrial revolution, and for the Turkish machinery sector, it’s not a choice—it’s a strategic imperative. The question is no longer if to adopt Industry 4.0 in Turkish Machinery, but how to do so effectively and at scale to maintain and grow a competitive edge in global markets. This article provides a definitive, data-driven analysis for B2B professionals who want to understand the current state, future opportunities, and critical steps needed to successfully navigate this transformative journey.

Why It Matters: The New Frontier of Global Competition

For decades, the Turkish machinery industry has relied on a potent combination of high-quality engineering, flexible production, and a strategic geographical location to compete internationally. However, as global rivals invest heavily in automation and smart manufacturing, these traditional advantages are no longer sufficient. Industry 4.0 in Turkish Machinery is the new frontier of competition.

According to a study on the digitalization of Turkey’s manufacturing industry, the adoption of Industry 4.0 technologies can improve efficiency and productivity by 30-50%, while decreasing resource consumption by 20-25%. Ignoring this transformation means falling behind on efficiency, losing ground on quality, and ultimately, risking market share to nations that are fully embracing smart manufacturing. For a sector that exports to over 200 countries, this is an existential challenge that demands immediate, strategic action. .

In-Depth Analysis: The State of Industry 4.0 in Turkish Machinery

The journey toward full digital transformation for Industry 4.0 in Turkish Machinery is ongoing, with significant progress in some areas and considerable room for growth in others. A 2022 survey of manufacturing firms found the average industrialization score was around 2.69 on a scale where a score between 3.0 and 3.99 represents a company in the process of digital transformation. This indicates a sector that is on the right path but still in the early stages of a full-scale digital revolution.

Key Technologies Driving Adoption

Turkish companies are not just talking about Industry 4.0; they are actively implementing its core technologies. The most common applications include:

- Industrial Automation and Robotics: This is the most widely adopted technology, with industrial automation in Turkey reaching a market size of $1.8 billion in 2022 and growing at an annual rate of 15%. A significant portion of this growth is driven by the machinery sector. Industrial robots are increasingly used for repetitive and high-precision tasks, with a particular concentration in the automotive industry. However, there is still significant room for growth, as Turkey currently uses an average of 36 robots per 10,000 workers, compared to the global average of 80.

- Internet of Things (IoT) and Sensor Systems: The use of IoT is crucial for connecting machines and collecting real-time data. Many Turkish manufacturers are embedding sensors in their machines to monitor key parameters like temperature, pressure, and vibration. This data is then used for production optimization and predictive maintenance.

- Big Data and Analytics: The data generated by IoT sensors is worthless without analysis. An increasing number of firms are using big data analysis to identify bottlenecks in their production lines, optimize energy consumption, and improve product quality.

- Additive Manufacturing (3D Printing): Although a niche technology, 3D printing is gaining traction, particularly for rapid prototyping and producing complex parts. This helps firms reduce costs and accelerate their design-to-production cycles.

Case Study: A Leading R&D Company in Konya

A prime example of a company embracing Industry 4.0 in Turkish Machinery is İmas Makina Sanayi A.Ş., a Konya-based milling machinery manufacturer. The company has a dedicated R&D center and has been recognized as one of the “Top 10 R&D Leaders” in the Turkish machinery industry for four consecutive years. The company’s R&D efforts are focused on process control, energy saving, and digitalization. A key innovation has been the introduction of new generation torque motors for roller mills, which provides a major energy-saving advantage. This approach of integrating high-value-added R&D with practical, energy-efficient solutions is the blueprint for success.

Actionable Tips: A Roadmap for Digital Transformation

For any machinery professional, from a small manufacturer to a large exporter, here is a clear roadmap for embracing Industry 4.0 in Turkish Machinery:

1. Conduct a Digital Maturity Assessment

- Identify Your Starting Point: Before you invest, you must know where you stand. Assess your current level of digitalization, identify your biggest pain points (e.g., unplanned downtime, energy waste), and determine which technologies will provide the highest return on investment.

- Prioritize Investments: Instead of trying to digitalize everything at once, focus on one or two key areas. For example, start with a pilot project in predictive maintenance or an automation system for a single production line.

2. Invest in Your Workforce

- Upskill Your Employees: Technology is only as good as the people who use it. Implement training programs to develop your workforce’s skills in data analysis, robotics, and smart systems management.

- Attract New Talent: The shift to Industry 4.0 requires new skill sets. Actively recruit data scientists, mechatronics engineers, and cybersecurity experts to drive your digital initiatives.

3. Leverage Government Support and Ecosystems

- Utilize Public Funding: The Turkish government, through institutions like TÜBİTAK and KOSGEB, provides grants and incentives for digitalization projects. Access these funds to reduce the financial burden of your investments.

- Collaborate with Academia: Partner with universities and research centers to get access to cutting-edge research and young, talented engineers.

Common Mistakes and How to Avoid Them

The road to digital transformation is full of potential pitfalls. Here are the most common mistakes and how to avoid them:

- A Piecemeal Approach: Simply buying a few smart machines without a cohesive strategy for integration is a recipe for failure. A successful transformation requires a holistic view of the entire production process and supply chain.

- Neglecting Cybersecurity: As your factory becomes more connected, it also becomes more vulnerable to cyberattacks. Cybersecurity is not an afterthought; it is a fundamental pillar of any Industry 4.0 strategy.

- Viewing It as an Expense, Not an Investment: The initial costs of digital transformation can seem high, but the long-term benefits in terms of efficiency, reduced waste, and increased competitiveness far outweigh the initial outlay.

Future Trends and Predictions for Industry 4.0 in Turkish Machinery

The ongoing adoption of Industry 4.0 in Turkish Machinery is setting the stage for a new era.

- The “Green and Digital” Twin Transition: The industry will be forced to simultaneously adopt digital technologies and meet sustainability goals. This will lead to a new generation of machines that are both smart and energy-efficient.

- The Rise of Industry 5.0: The next wave will focus on human-robot collaboration, creating a production model that combines robotic precision with human creativity.

- Service-Oriented Business Models: Turkish manufacturers will increasingly move toward offering “Machine-as-a-Service” models, where the machine, software, and maintenance are bundled into a subscription, creating new revenue streams.

The adoption of Industry 4.0 in Turkish Machinery is more than just a technological upgrade; it is a catalyst for economic growth, a driver of innovation, and a necessary step to secure a place in the competitive global market. While the journey is still in its early stages, the momentum is undeniable. By making strategic investments in technology, nurturing a skilled workforce, and leveraging government support, Turkish machinery manufacturers can solidify their position as leaders in the global industrial landscape. The businesses that embrace this digital revolution today will be the ones that thrive tomorrow.