The flow of global machinery trade is a powerful current that shapes economies and industries. For decades, this current was dominated by a few large players. But today, a new center of gravity is emerging. Turkey, once a peripheral player, has transformed into a powerful force, commanding respect and attention on the world stage. How did this transformation happen? What unique advantages does Turkey bring to the table? This article goes beyond the headlines and statistics to provide a deep, data-driven analysis for B2B professionals seeking to understand this seismic shift in the global industrial landscape.

Why It Matters: Shifting Supply Chains and a Call for Resilience

The world of international trade is more complex and volatile than ever before. Recent global events have exposed the fragility of long-distance supply chains and highlighted the risks of over-reliance on a single manufacturing hub. In this new reality, companies are actively seeking resilient, flexible, and geographically advantageous partners. Turkey, with its unique position at the crossroads of Europe, Asia, and Africa, has stepped up to fill this critical need. This is a story not just of economic growth, but of strategic realignment, where Turkey’s role in global machinery trade is evolving from a supplier to a strategic partner.

Turkey’s Position in Global Machinery Trade: An In-Depth Analysis

Turkey’s ascent in the global machinery trade is backed by a compelling set of data from institutions like the Machinery and Accessories Exporters’ Union (MAIB) and the Turkish Statistical Institute (TURKSTAT).

Export Power: A Story of Exponential Growth

Over the past two decades, Turkey’s machinery exports have seen an unprecedented boom. From just over $2 billion in the early 2000s, exports of machinery and mechanical appliances have grown to exceed $28 billion in 2024. This growth rate is significantly higher than the global average, reflecting a focused effort on increasing production capacity and market penetration. The trend continues into 2025, with exports holding steady despite global economic headwinds. The average export price per kilogram, a key indicator of value, has also been on a steady rise, reaching approximately $7.8, which is well above Turkey’s national average. This is a clear signal that Turkish manufacturers are not just competing on low cost but on quality and high-value-added products.

Strategic Location and Logistics

One of Turkey’s most powerful assets in the global machinery trade is its geography. Situated at the nexus of three continents, Turkey offers unparalleled logistical advantages.

- Proximity to Key Markets: The country is a natural hub for accessing the European Union, the Middle East, North Africa (MENA), and the Commonwealth of Independent States (CIS). A significant portion of Turkey’s machinery exports, approximately 60%, is directed to the EU and the USA.

- Time-to-Market Advantage: With well-developed road, rail, and sea networks, Turkish manufacturers can deliver goods to European customers much faster than their competitors in the Far East, a crucial factor in today’s fast-paced business environment.

- Modern Infrastructure: Turkey’s state-of-the-art ports in Istanbul, Izmir, and Mersin, coupled with a robust domestic logistics network, provide a seamless flow of goods, reducing shipping times and costs for international buyers.

A Diverse and Resilient Sub-Sectoral Base

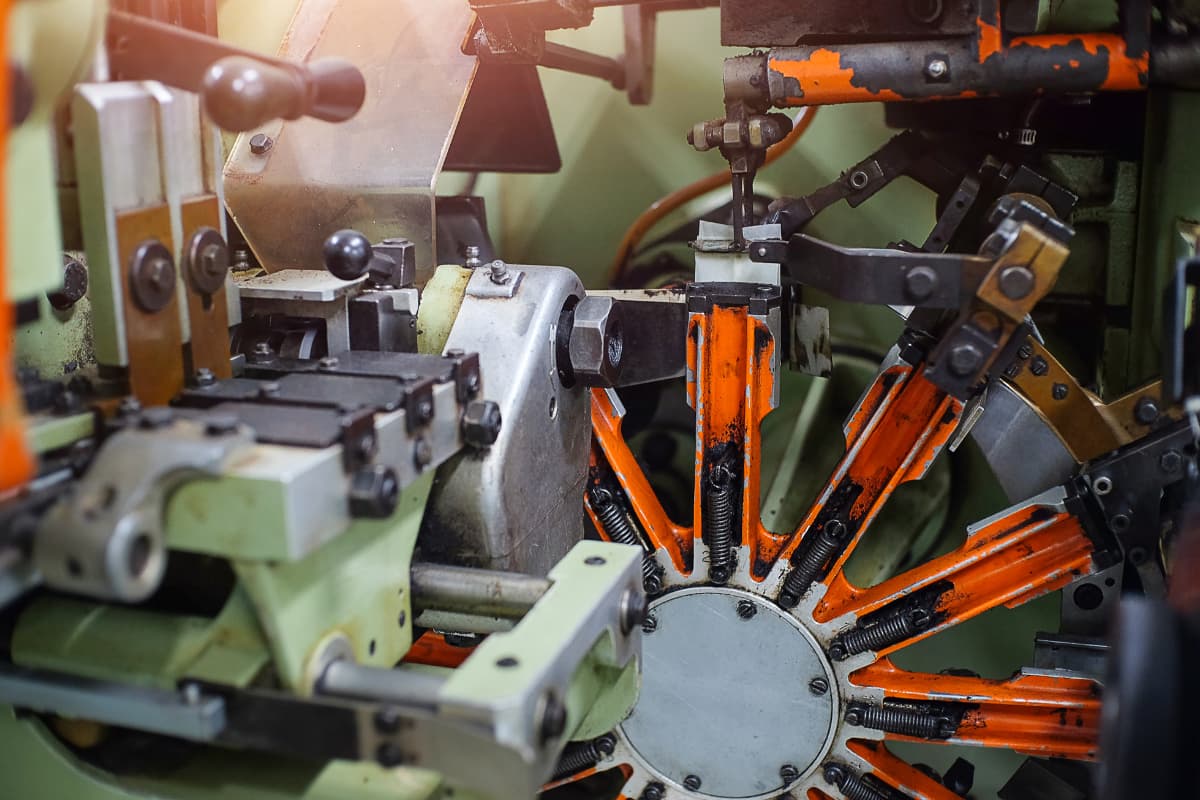

Turkey’s success isn’t built on a single type of machinery. The country has developed deep expertise across a wide range of sub-sectors.

| Sub-sector | Key Strengths | Primary Export Markets |

| Agricultural Machinery | Durable, cost-effective, and tailored to diverse farming conditions. | Middle East, Africa, Central Asia |

| Construction and Mining Machinery | Known for robust performance and strong after-sales support. | Russia, Iraq, Algeria, UK |

| Textile Machinery | Historically strong, with a focus on high-tech looms and spinning machines. | Uzbekistan, Egypt, Bangladesh |

| Food Processing and Packaging Machinery | High quality, hygienic, and compliant with international standards. | Iraq, Saudi Arabia, Germany |

| Metalworking and Tooling Machinery | A growing focus on high-precision CNC machines and laser cutters. | Germany, USA, Italy |

Case Study: The Turkish milling machinery sector, for example, is making significant strides. Despite a challenging global economic climate in 2024, the sector’s exports grew by 5%. Manufacturers are leveraging Industry 4.0 and 5.0 technologies to enhance quality and target new markets, especially in Africa, where food supply security is a top priority. This adaptability and focus on key global needs are the hallmarks of Turkey’s success.

A Strategic Roadmap for Success in Global Machinery Trade

For Turkish exporters to continue their growth trajectory, a clear strategic roadmap is essential.

1. Focus on High-Value-Added Production

The future of global machinery trade is about more than just quantity. It’s about value.

- Invest in R&D: Increase investments in research and development to create innovative products with higher technological content. The number of R&D centers in Turkey’s machinery sector has been growing, a trend that must continue.

- Integrate Industry 4.0/5.0: Embed smart sensors (IoT), AI, and robotic systems into your machines. This not only boosts efficiency but also provides a major selling point for international buyers seeking advanced, data-driven solutions.

- Pursue Niche Specialization: Instead of competing in broad categories, focus on niche markets that require specialized expertise, such as high-precision machines for aerospace or medical equipment.

2. Diversify Markets and Build a Strong Global Brand

While traditional markets like Germany and the USA are crucial, the fastest growth is often found elsewhere.

- Target Emerging Economies: Focus on fast-growing markets in Africa, Latin America, and Southeast Asia. These regions are investing heavily in infrastructure and industrialization, creating a massive demand for machinery.

- Strengthen Your Global Presence: Participate in major international trade shows like Hannover Messe, BAUMA, and EMO Milano. Use digital marketing and content strategy to build authority and trust with global buyers.

3. Emphasize Quality and After-Sales Support

In a crowded market, reliability and service are powerful differentiators.

- Adhere to International Standards: Ensure your products meet and exceed global quality and safety standards (e.g., CE, ISO). This is a non-negotiable for entering regulated markets.

- Build a Robust After-Sales Network: A sale is the beginning, not the end, of the customer relationship. Invest in a strong after-sales support network in your key export markets to ensure fast spare parts delivery and expert technical assistance.

Common Pitfalls and How to Avoid Them

Even with a strong strategy, certain pitfalls can derail success in the global machinery trade.

- Ignoring Geopolitical Risks: Over-reliance on a single market exposes a company to significant geopolitical risks, as evidenced by the sharp decline in exports to Russia. A diversified portfolio is essential for resilience.

- Neglecting the “Green” Transition: Ignoring regulations like the EU’s Carbon Border Adjustment Mechanism (CBAM) could lead to tariff disadvantages and a loss of market access. Investing in energy-efficient and sustainable production is a must.

- Failing to Invest in R&D: Relying on existing technologies and competing only on price is a short-term strategy. Continuous investment in R&D is the only way to create high-value-added products that can compete with global leaders.

Future Trends and Predictions for Global Machinery Trade

The future of global machinery trade will be shaped by a few key trends, and Turkey is well-positioned to capitalize on them.

- Digital and Green Twin Transition: The simultaneous push for digitalization (Industry 4.0) and sustainability (Green Deal) will force manufacturers to create machines that are both smart and eco-friendly. Turkey’s “Twin Transition Project” for the machinery sector is a forward-thinking response to this trend.

- Nearshoring and Supply Chain Diversification: The demand for regional and reliable suppliers will continue to grow. Turkey’s strategic location and established manufacturing base make it a top choice for European and American companies seeking to reduce their supply chain risks.

- The Rise of Automation and Robotics: Automation will become more accessible and widespread, with collaborative robots (cobots) leading the charge. Turkey’s robotics market is growing, presenting an opportunity for manufacturers to both produce and integrate these systems.

Turkey’s rising role in global machinery trade is not a fleeting trend; it is the result of decades of hard work, strategic investments, and a relentless focus on quality and innovation. From its strategic location to its diverse manufacturing base and commitment to technological advancement, Turkey is establishing itself as a resilient and reliable partner in the global industrial ecosystem. The future is bright for Turkish machinery, but continued success will require a sharp focus on innovation, sustainability, and building a strong, globally recognized brand.